Gum Rosin Grade WW - China

|

IUPAC Name |

: (4aR)-1,4a-dimethyl-7-propan-2-yl-2,3,4,4b,5,6,10,10a-octahydrophenanthrene-1-carboxylic acid |

|

Cas Number |

: 8050-90-7 |

|

HS Code |

: 3806.10.00 |

|

Formula |

: C20H30O2 |

Basic Info

|

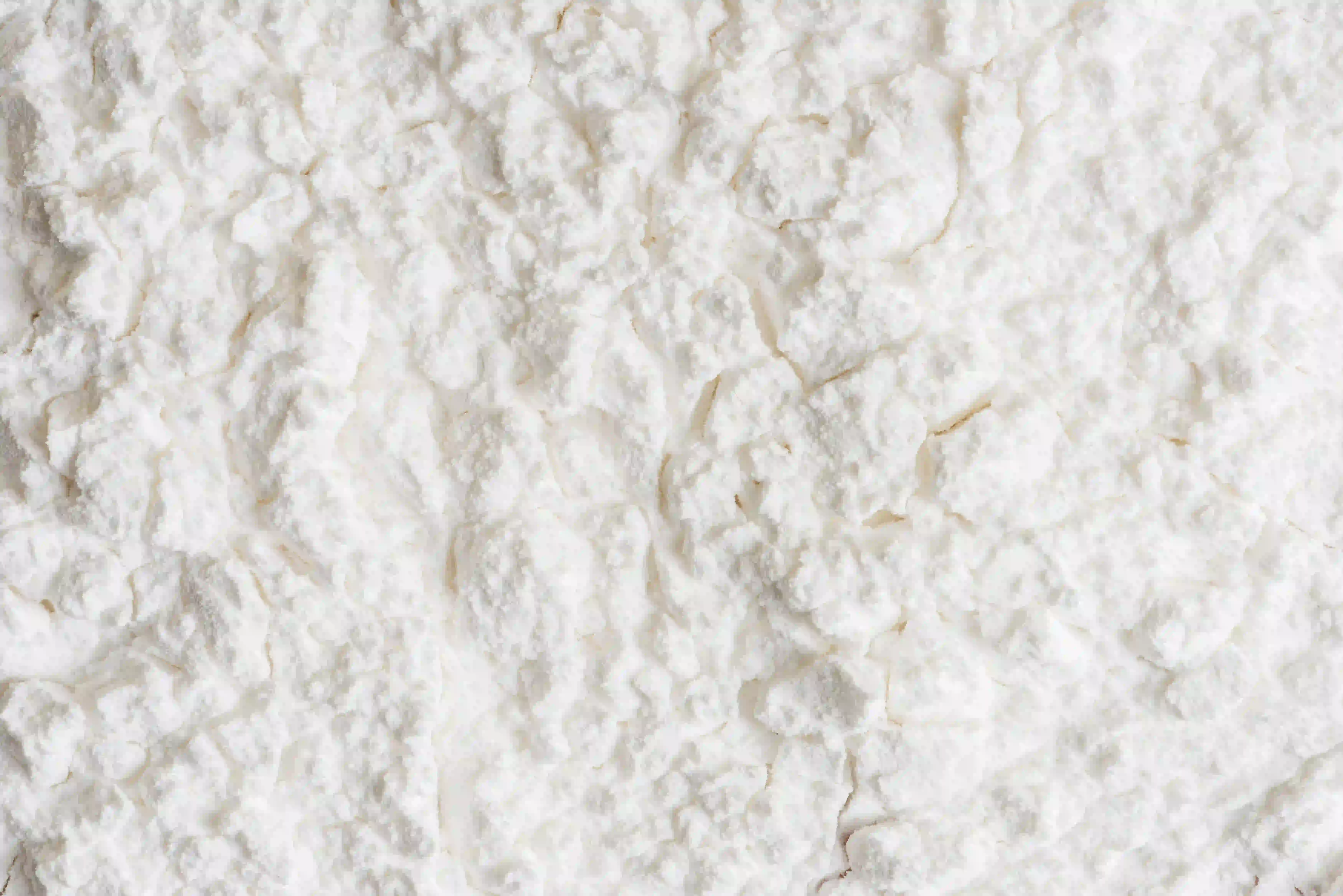

Appearance Name |

: Pale Yellow Cristal |

|

Common Names |

: Gum Rosin Grade WW |

|

Packaging |

: (225 kg Galvanized Iron Drum), (25 kg Net Kraft Paper Bag) |

---bangladesh.webp)